Perlite, an igneous rock, is formed by the hydration of rhyolitic obsidian, a rock which is the result of rapid chilling of molten high silica rhyolitic lava. The distinguishing feature which sets perlite apart from other volcanic siliceous rocks is that when heated above 800°C, it expands up to 20 times its original size, becoming a lightweight expanded material. This expansion is due to the presence of water trapped within the crude ore.

Gulf Perlite offers consistent delivery of Perlite Filter Aid depending on customer requirement by controlling the chain of processing directly from the ore. Carefully selected Perlite is transported to our state of the art modern facilities in the Jebel Ali, Dubai.

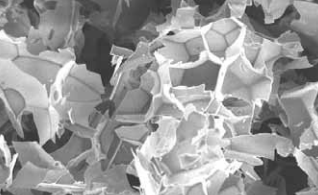

The Perlite ore is subjected to rapid heating above 800°C under carefully controlled conditions. As a result, the Perlite structure ‘pops’ consequence of the build-up of internal pressure due to combined moisture forming a multi-cellular, irregular glass bubble structure. These glass bubbles are further milled to varying particle sizes to form perlite filter aids.

With its unique morphology, expanded milled Perlite has excellent properties for removal of difficult to filter suspended solids due to its jagged interlocking structure (Fig.1). In addition, its light density allows Perlite filter aids to retain large volumes of suspended solids while maintaining excellent permeability.

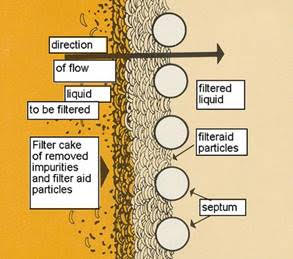

Perlite filter aids are lightweight, inert, impart no taste or odour to liquids being filtered and are virtually insoluble in mineral and organic acids at all temperatures. Solubility in strong alkaline solutions varies depending on temperature and contact time. Without using a filter aid the solid particles in the liquid will soon accumulate on filtering surfaces and block them.

A perlite filter aid makes a filtering layer (cake) that transfers the actual filtering from the septum to the whole mass of filter aid. Filtration occurs in the tiny pores formed by the fine particles of filter aid.

Additional benefits of perlite filter aids come at the end of the filter cycle. Perlite filter cakes remain porous and do not compact. Filter cakes built up under pressure release easier when perlite is used. This release facilitates cleaning, potentially reduces manpower requirements, and increases productivity. The lower weight of perlite filter cakes may also reduce disposal costs.

Gulf Perlite filter aids are both sterile and inert and are used for filtering liquids in the beverage, food and pharmaceutical industries. No tastes, colours or odours are imparted, and, subject to meeting the standards listed in the Food Chemicals Codex (published by the United States’ National Academy of Sciences), are deemed safe for their intended use.

Filtration is the separation of solids from liquids by forcing the liquid to flow through a porous medium and depositing the solids on the medium. A filter aid is a finely divided material which, when added to the liquor to be filtered, helps control flow and solids removal. The septum, usually screen or cloth, serves principally as a support for the cake. The filter aid forms a porous layer on the septum and thus the filter aid is the filtering medium that traps the solids being removed and prevents them from blinding the septum. Filter aid filtration is mechanical, not chemical in nature. Irregularly shaped particles interlace and overlay in a fashion that leaves 85 to 95 % voids or open spaces. These voids form billions of microscopically fine interstices between the filter aid particles. The size of these openings is so minute that the unwanted solids are strained from the liquid. The vast number of openings compensates for their small size resulting in fast flow rates and brilliant clarity.

Good filter aids are light in weight, chemically inert and form high porosity filter cakes to maintain free flow of the liquid. The structure of the particles must be such that they will not pack too closely. This not only permits high initial liquid flow but also provides pore spaces to trap and contain the filterable solids and leave a high percentage of channels remaining open for flow. Particle size distribution must be tailored to permit precoating on coarse wire and yet give the desired flow rate and clarity. Gulf Perlite Premium Quality Filter Aids meet these criteria. They are available in a variety of grades to suit the solids removal requirement of any application.

Solid / liquid separation with perlite filter aids on pressure type filter systems are a two-step process.

First step is the formation of precoat (Fig.2). It is a thin layer, 1.5 to 3.0 mm, which protects the septum and ensures clarity by stopping the solids at the surface. The filter aid grade used for precoat must be carefully selected to allow the fastest possible flow yet trap the solids. Slurry is made from filtered liquid, or sometimes water, and filter aid. The filter septum serves as a support for the perlite precoat and does not function to remove particulates from the liquid.

The amount of Perlite filter aid required to produce a precoat cake is between (400 – 1200 g/m²) of filter area. Systems with larger surface area may require a higher precoat rate to achieve a fully covered filter area. The precoat is formed by recirculating the filter aid slurry through the filter. The coarser particles deposit themselves first on the septum followed by smaller ones.

Please contact us for any clarification.