Gulf Perlite Pipe Sections are a pre-formed, high-temperature, corrosion resistant, water repellent, pipe and block insulation section, uniformly reinforced with a high strength fiber for use on systems operating up to 1200°F (650°C) as per ASTM C-610 suitable for high-temperature pipe insulation, e.g. Sulfur Conveying Lines. Gulf Perlite Pipe Sections are an inorganic, non-combustible section which meet and exceed the physical property requirements of ASTM C-610.

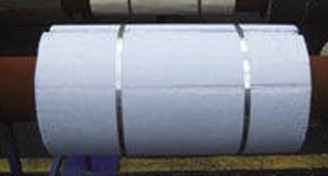

Gulf Perlite Pre-Formed Insulating Pipes inhibit corrosion and are rigidly strong resisting damage.

Gulf Perlite Pre-Formed Pipes prevent the accumulation of Chloride Ions that may penetrate and corrode the pipes. They also resist against formation of acid and alkalis attacks.

Day 1, Installation of Gulf Perlite Molded Pipe Insulation

Day 84, Subjected to cycle conditions(e.g.:temperature, weathering and saline water) to accelerate corroding

Perlite Insulated segments displays minimal corrosion

|

ASTM C610 Requirement |

Gulf Perlite Pipe Section |

|||||

|

Density (Kg/m³) |

Max. 240 |

217 |

||||

|

Flexural Strength, kPa |

Min. 310 |

380 |

||||

|

Compressive Resistance @ 5% Deformation or yield which occurs first, kPa |

Min. 483 |

526 |

||||

|

Weight Loss by Tumbling, % loss in weight after 10 minutes, % |

Max. 70 |

60.5 |

||||

|

Moisture Content, % by weight |

Max. 10 |

2.5 |

||||

|

Water Absorption of Thermal Insulation after heat aging 316°C and 48h Water Immresion, % weight gained |

Max. 50 |

42 |

||||

|

Linear Shrinkage, % @ 649°C for 24h Max |

Length |

2% |

Length |

2.00% |

||

|

Width |

2% |

Width |

2.00% |

|||

|

Thickness |

8% |

Thickness |

3.30% |

|||

|

Stress Corrosion Cracking of Austentic Stainless Steel |

Pass |

Pass |

||||

|

Surface Burning Characteristic |

||||||

|

Flame Spread |

Max. 0 |

Pass |

||||

|

Smoke Development |

Max. 5 |

Pass |

||||

|

Non Combustibility |

||||||

|

Non Combustible |

Pass |

Pass |

||||

|

Hot Surface Performance |

||||||

|

Warpage, mm |

Max. 6 mm |

1.5 mm |

||||

|

Cracking |

No cracks completely through the insulation thickness. Surface cracks on hot face are acceptable |

Pass |

||||

Please contact us for any clarification.